Maintenance Tips Extend Hydraullic Breaker Attachment Life

페이지 정보

24-10-12 00:36본문

이메일 :연락처 :

Any type of contamination is the enemy; due to this fact, correct upkeep is vital to survival. Hammers are sometimes used along side other attachments, comparable to buckets. This can create several points if not dealt with correctly. First, be certain the hoses are correctly capped to prevent hydraulic oil contamination. Second, if you share the attachment between carriers, verify the flows and pressures. Over-rushing a hammer is a sure solution to shorten life expectancy. Don’t simply mount the closest out there hammer to the obtainable carrier. "Correctly sizing a breaker to match its carrier’s weight is a method to extend a hydraulic breaker’s lifespan," says Kevin Loomis, business line manager, development instruments, Atlas Copco. "Using hydraulic breakers which can be too small can damage mounting adapters and inside elements because the bigger provider applies a lot drive on the breaker.

Hydraulic breaker (hydraulic hammer) is a type of building machinery that is mounted on excavators, backhoes, skid steers, mini-excavators, and stationary plants. Hydraulic breakers (hydraulic hammers) are broadly used in mining and landscaping applications. Though it can be each stationary and mobile, the hydraulic breaker is mostly used as a cellular device because it is more versatile. At present, there are numerous different types of rock breakers and so they differ when it comes to weight, size and utilization.

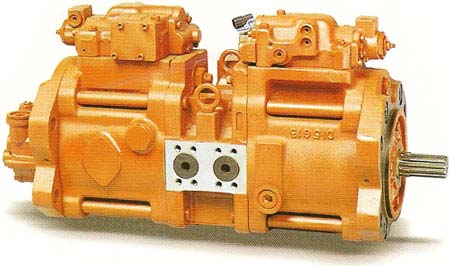

Due to air inside the Mini Excavator Hydraulic Pump, when it displaces the fluid, it produces a bizarre rattling sound called knocking. A number of things may cause knocking in the hydraulic pump. These embody the working performance, its condition, grease oil quality, and mechanical interference beneath high strain. Normal lubrication of a new hydraulic pump (hydraulic motor) is one of the best ways to forestall and remove knocking noise (hydraulic pump noise or hydraulic motor noise) and prolong the life of the fluid energy system. Firstly, it helps to forestall breakdowns and dear repairs. Like every other piece of tools, hydraulic breakers are subject to put on and tear. Regular upkeep, such as lubricating transferring components and inspecting for any indicators of harm, can assist identify and deal with potential points before they change into main issues. This not solely saves time and money but also ensures that the hydraulic breaker is all the time in optimal working situation. Non-obligatory angle blade has float. "It’s important to hold the small excavator’s performance traits to all of the applications for which these machines are used," he says. New Deere excavators have a typical menu construction and really feel. There may be a quick entry button and jog dial controller on the Command Arm for quick and straightforward use of these menus.

댓글목록

등록된 댓글이 없습니다.